Picture this: you're running a production line, but you're not physically present at the facility. How do you ensure everything runs smoothly? Enter remote batch monitoring, a solution that's revolutionizing the way industries operate. This technology allows businesses to keep an eye on batch processes from anywhere in the world, ensuring efficiency, accuracy, and cost-effectiveness. But what exactly is remote batch monitoring, and why should you care? Let's dive in and find out!

In today's fast-paced world, businesses are always on the lookout for ways to streamline operations and reduce costs. Remote batch monitoring offers a cutting-edge solution that ticks all the right boxes. By leveraging advanced software and hardware, companies can now monitor and control their batch processes without being physically present. This not only saves time and money but also enhances productivity and reduces the risk of errors.

But remote batch monitoring is more than just a buzzword. It's a practical solution that's already being adopted by industries across the globe. From pharmaceuticals to food processing, companies are reaping the benefits of real-time data analysis, predictive maintenance, and enhanced decision-making. So, if you're curious about how this technology can transform your business, stick around. We've got all the answers you're looking for!

Read also:Mastering Ntta Customer Service The Ultimate Guide To Exceptional Support

What Exactly is Remote Batch Monitoring?

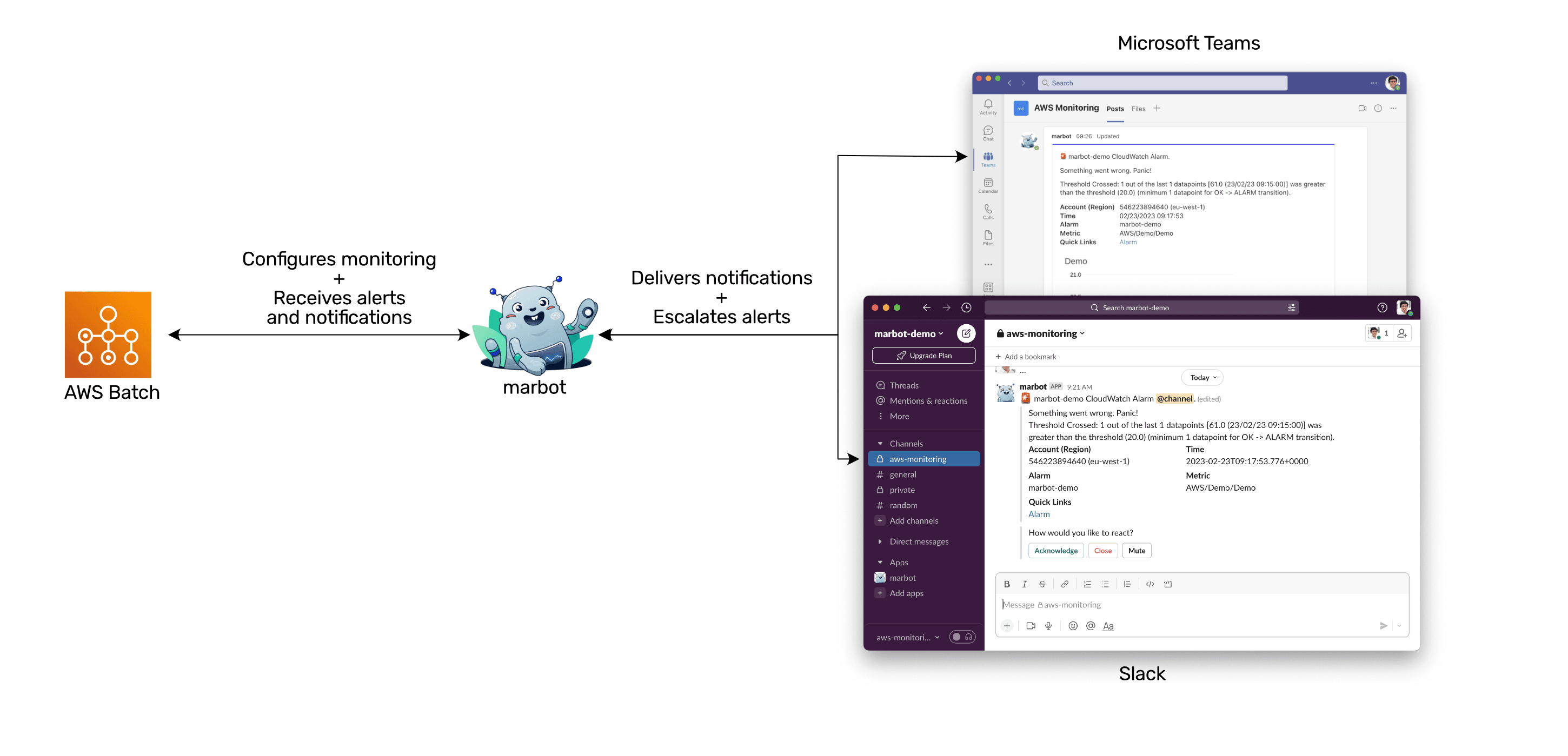

Let's start with the basics. Remote batch monitoring is essentially the process of overseeing and managing batch operations from a remote location. It involves using sensors, IoT devices, and software platforms to collect and analyze data in real-time. This data is then transmitted to a central system, where it can be accessed and interpreted by authorized personnel.

But why is it such a big deal? Well, traditional monitoring methods often require someone to be physically present at the production site. This can be time-consuming, costly, and sometimes even impractical. Remote batch monitoring eliminates these barriers, allowing businesses to operate more efficiently and effectively.

Here are a few key features of remote batch monitoring:

- Real-time data collection and analysis

- Predictive maintenance capabilities

- Enhanced decision-making through data visualization

- Improved process efficiency and reduced downtime

Why is Remote Batch Monitoring Important?

In a world where time is money, remote batch monitoring offers a solution that's too good to ignore. By enabling businesses to monitor their operations from anywhere, it helps reduce costs, increase productivity, and improve overall efficiency. But the benefits don't stop there. Here are a few reasons why remote batch monitoring is so important:

Cost Savings

One of the biggest advantages of remote batch monitoring is the potential for significant cost savings. By eliminating the need for on-site personnel, businesses can reduce labor costs and allocate resources more effectively. Additionally, predictive maintenance capabilities help prevent costly equipment failures and reduce downtime.

Increased Productivity

With real-time data analysis and enhanced decision-making tools, remote batch monitoring allows businesses to optimize their operations and increase productivity. By identifying inefficiencies and addressing them promptly, companies can streamline their processes and achieve better results.

Read also:Spokane Convention Center The Hub Of Events And Entertainment In Washington

Improved Accuracy

Human error is a common issue in traditional monitoring methods. Remote batch monitoring reduces the risk of errors by automating data collection and analysis. This ensures that businesses have access to accurate, reliable data that can be used to make informed decisions.

How Does Remote Batch Monitoring Work?

Now that we know what remote batch monitoring is and why it's important, let's take a closer look at how it works. The process typically involves the following steps:

Data Collection

Sensors and IoT devices are installed at the production site to collect data on various parameters such as temperature, pressure, and flow rate. This data is then transmitted to a central system for analysis.

Data Transmission

The collected data is transmitted to a central system using secure communication protocols. This ensures that the data is accessible to authorized personnel from anywhere in the world.

Data Analysis

Once the data reaches the central system, it's analyzed using advanced algorithms and machine learning techniques. This allows businesses to gain valuable insights into their operations and make data-driven decisions.

Industries That Benefit from Remote Batch Monitoring

Remote batch monitoring isn't just for one specific industry. In fact, it's being adopted by businesses across the globe in a variety of sectors. Here are a few examples:

Pharmaceuticals

In the pharmaceutical industry, remote batch monitoring is used to ensure the quality and consistency of products. By monitoring key parameters such as temperature and humidity, companies can maintain optimal conditions for production and storage.

Food Processing

The food processing industry relies heavily on remote batch monitoring to ensure food safety and quality. By monitoring factors such as temperature and pH levels, companies can prevent contamination and ensure compliance with regulations.

Chemical Manufacturing

In the chemical manufacturing sector, remote batch monitoring helps companies optimize their processes and reduce waste. By analyzing data on reaction rates and yields, businesses can identify inefficiencies and make improvements.

Challenges and Solutions in Remote Batch Monitoring

While remote batch monitoring offers numerous benefits, it's not without its challenges. Here are a few common issues and how they can be addressed:

Data Security

One of the biggest concerns with remote batch monitoring is data security. To address this, companies can implement robust security measures such as encryption and access controls to protect sensitive information.

Integration with Existing Systems

Integrating remote batch monitoring systems with existing infrastructure can be a challenge. To overcome this, businesses can work with experienced vendors who specialize in system integration and ensure a seamless transition.

Training and Support

Training employees to use remote batch monitoring systems effectively is crucial for success. Companies can provide comprehensive training programs and ongoing support to ensure that staff are equipped with the necessary skills.

Future Trends in Remote Batch Monitoring

As technology continues to evolve, so does remote batch monitoring. Here are a few trends to watch out for in the coming years:

Artificial Intelligence and Machine Learning

AI and machine learning are set to play a major role in remote batch monitoring, enabling more accurate predictions and smarter decision-making. By leveraging these technologies, businesses can achieve even greater efficiency and productivity.

Edge Computing

Edge computing is another trend that's gaining traction in the remote batch monitoring space. By processing data closer to the source, companies can reduce latency and improve response times, leading to better overall performance.

5G Connectivity

The rollout of 5G networks is expected to enhance the capabilities of remote batch monitoring systems, providing faster and more reliable data transmission. This will enable businesses to monitor their operations in real-time with greater precision and accuracy.

Implementing Remote Batch Monitoring in Your Business

So, you're convinced that remote batch monitoring is the way to go. But how do you go about implementing it in your business? Here are a few steps to get you started:

Assess Your Needs

The first step is to assess your business's specific needs and identify the areas where remote batch monitoring can add value. This will help you determine the right solution for your operations.

Choose the Right Vendor

With so many vendors offering remote batch monitoring solutions, it's important to choose one that aligns with your business goals. Look for a vendor with a proven track record and strong customer support.

Plan and Execute

Once you've chosen a vendor, it's time to plan and execute the implementation process. This may involve installing hardware, configuring software, and training employees. With careful planning and execution, you can ensure a smooth transition to remote batch monitoring.

Conclusion

Remote batch monitoring is a game-changer for modern businesses, offering a range of benefits that can transform the way operations are managed. By enabling real-time data analysis, predictive maintenance, and enhanced decision-making, it helps businesses save time, reduce costs, and improve efficiency.

So, if you're looking to take your business to the next level, consider implementing remote batch monitoring. With the right solution and support, you can unlock new levels of productivity and success. And don't forget to share your thoughts and experiences in the comments below. We'd love to hear from you!

Table of Contents

For easy navigation, here's a list of all the sections and subsections in this article:

- What Exactly is Remote Batch Monitoring?

- Why is Remote Batch Monitoring Important?

- How Does Remote Batch Monitoring Work?

- Industries That Benefit from Remote Batch Monitoring

- Challenges and Solutions in Remote Batch Monitoring

- Future Trends in Remote Batch Monitoring

- Implementing Remote Batch Monitoring in Your Business

- Conclusion